From Orchid to Olive Oil: The Art of Making Olive Oil

Get ready for a flavorful journey from grove to table! As Autumn arrives, farmers swing into action, harvesting olives by hand or with buzzing machines. These little green and black treasures are quickly whisked away to the mill to keep them fresh and fabulous.

At the mill, the olives enjoy a refreshing wash before being crushed into a smooth paste. The magic happens when the paste is mixed, allowing the oil droplets to unite for a flavor explosion!

After separating the oil from solids, it’s filtered and stored in dark bottles to preserve its vibrant character.

And just like that, you have liquid gold ready to elevate your meals! Each bottle tells the story of an exciting adventure, capturing the essence of the olives and the art of harvesting. So, drizzle away and savor the journey!

Let us dive deeper into each step of the process!

Harvest to Bottle: The careful Craft of Olive Harvesting

When September rolls around, farmers eagerly keep an eye on their olives, watching them transition from vibrant green to deep purple or black. This is the moment to decide the perfect time to pick!

Depending on the scale of the Olive Plantation and the decision of the farmers, there are 2 distinct ways where olives are harvested

Traditional

This method is a very manual process. Farmers harvest by hand picking olives, so that they do not get damaged in the process.

It is a very gentle process and allows for careful selection of the olives.

This would allow for the highest grades of olives to be harvested and transport safely, minimising the damage which can fall upon the olive fruit.

Tools such as Combs and Rakes will be used commonly used to dislodge the olive fruit from the tree

After which, it will drop onto a Net Spread below to reduce the chances of bruising the olives

Machenical

This is the more common method and uses machines to vibrate the olives trees.

These machines grip the trunks of the Olive Trees and vibrate.

This allows for fast harvesting while also reduncing labor cost and time.

After all is done, the olives are transported to the factory to be preapred to be changed into Olive Oil

However, in another universe, these same olives might undergo a different transformation — they will be packed and sold as Olives. If you’re curious about this alternate path, we invite you to read the process of olive.

Pure Perfection: Washing, Sorting and selecting the Finest Olives!

Now that the olives are back at the factory, they need to be washed!

Once the precious olives arrive at the mill, it’s time for a little pampering!

They get a refreshing wash to remove all the dirt, leaves, and twigs picked up during harvest.

Think of it as a spa day for olives—they’re washed clean and ready for their big transformation!

After their spa treatment, the olives go through a quality check.

Only the finest, ripest olives make the cut! Any damaged or unripe ones are gently escorted out.

It’s VIP-only from here on out, ensuring the best fruit goes into making that liquid gold.

Crushing and Grinding: Breaking Down to Break Free

Next, it’s time to get down to business. The olives (pits included) are crushed into a thick, gooey paste.

Whether it’s done the old-school way with stone mills or the speedy modern hammer mills, the goal is the same—crack open those olives and unleash their juicy goodness.

The paste then gets an extra push, breaking down every bit of olive cell to release as much oil as possible.

It’s like squeezing out every drop of awesomeness from each olive.

Malaxation: The Magic Mix

Now for the secret sauce—malaxation! The olive paste is slowly stirred, allowing tiny droplets of oil to come together, forming bigger, shiny droplets. It’s like a dance where all the little oil droplets join hands and get ready to shine.

Temperature matters here! The paste stays nice and cool (below 27°C/80°F) to keep all the delicious flavors and nutrients intact. No cooking the olives here—it’s all about cold extraction to keep it fresh.

As the paste is mixed, the magic happens: the flavors get bolder, the aromas intensify, and the olive oil becomes the tasty treasure we all know and love.

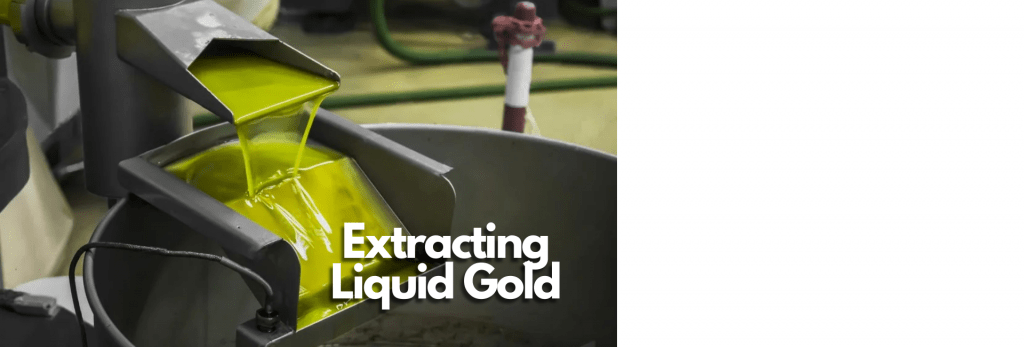

Separation: Extracting Liquid Gold

Once the olive paste has been thoroughly mixed during malaxation, it’s time to separate the oil from the rest of the mixture.

The paste contains water, oil, and solid bits of olive pulp, and they need to be split apart. This is typically done using a centrifuge, which spins the paste at high speeds.

The centrifugal force causes the heavier solids and water to move outward, while the lighter olive oil stays in the middle, making it easier to extract.

Storage and Bottling: Preserving the Freshness

Storing in Dark Containers: The freshly produced olive oil is stored in stainless steel tanks or dark glass bottles to protect it from light and air, which can degrade the quality. The storage temperature is also kept cool to maintain its flavor and nutrients.

Quality Control Checks: Before the oil is bottled and shipped out, quality tests are done to ensure it meets the standards for extra virgin or other grades of olive oil.

Now that you know...

So, you thought olive oil just magically appears on the shelf? Now you see it’s anything but simple!

From year-round care and handpicked harvests to washing, crushing, and expertly separating that golden liquid from the rest, every step is crafted with care.

Olive oil production is truly an art form, shaped by skill, dedication, and a bit of patience.

Now that you know the journey from grove to bottle, why not explore the results for yourself?

Visit our store to experience the fruits of this incredible process—our selection of premium olive oils is waiting for you!